Intranet application Raw Material Stock

Before this application was implemented, it happened sometimes, that urgent shortage of raw material occured and demand on express delivery was required. This was expensive. Another time, just for sure, were material resources kept on uselessly high-level. This was expensive again. It would be possible to implement system for just in time delivery, but it would be perhaps the most expensive case. We tested probes for raw materials level measurement in bunkers, but raw materials thanks to humidity, glue on wall of bunkers and measurement was not reliable.

We formulated idea, which sounded somehow like this: we have control system for raw material weighting in Batch House, which saves data to database. So we can find out daily consumption of raw materials. We have running applications Production Plan and Product Type Catalog. So we can find out planned material consumption. We need some data about material orders and deliveries, material inventory data and then let the machine to calculate actual quantity of raw material in stock.

Such idea seemed to me crazy enough, so I started to realize that. Now I'm going to introduce you the final intranet application. This application is in Czech language version only and screenshots may be difficult to read, sorry.

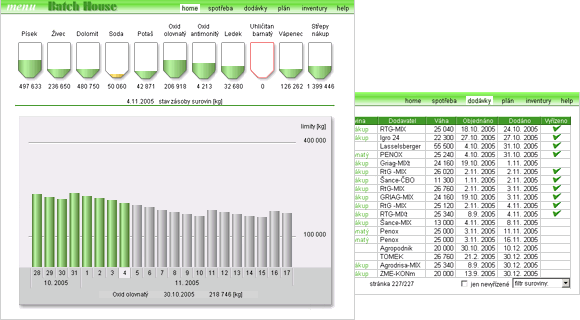

In the left side of picture is application homepage. We can see something like silos or bunkers and inside them actual level of raw material. When we click on bunker, we get trend of daily reserve of that material in bar graph below. Decreasing tendency means daily consumption, step up is planned, or realized delivery. Green columns mark real quantity (7 days back), grey columns mark planned quantity with view of 14 days forward. When point mouse on bar, corresponding numeric data (date, reserve) is displayed below graph.

For each material it is possible to set minimum, maximum reserve limits, and graphic scale. At lower than minimum reserve, yellow colour is used for material level representation in bunker and for column graph. If reserve is zero, red picture of empty bunker is displayed.

Real and planned material consumption, deliveries and inventory are displayed in various tables. Sample of such a table (material delivery) is in the right part of picture.

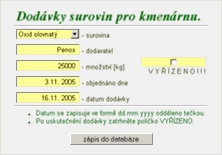

In small screenshot on right is form for material delivery data input. This form is used when new material order is released. When raw material is delivered the same form is utilized for confirmation of delivery. It is possible to do correction in date and quantity at delivering time.

Very similar form is used for material inventory. It is possible to make inventory at any day, usually when reserve is close to zero. That is right time for good quantity estimation. So only two forms are necessary for complete application running.

To well running application, workers from different departments have to enter data. Those workers need to be assigned to one of following roles:

- Logistics. Enters data of new raw materials orders.

- Stock. Confirms delivery of material to appropriate order, can change real delivered quantity.

- Batch house master. Enters performed inventory data. Something like reset bunker reserve.

- Planner. Retain actual production plan, so application knows planned product types (data comes from another application).

- Production manager. Supports product type standards. We need to know weight and machine cycle of planned product for determination of planned daily material consumption (data comes from another application).

- Batch house control system. Provides real daily consumption of raw materials.

The application has been running successfully since 2001. Only annual inventory is required once a year to synchronize data.

updated 12.12.2006